- Description

Description

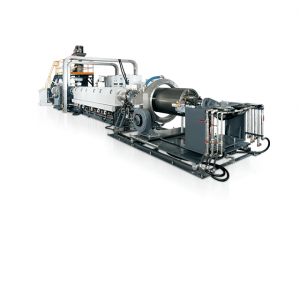

We offer a range of tandem foam board extrusion lines with complete downstream for XPS production using CO2 as a blowing agent.

We are able to offer board thickness from 20mm to 140mm and widths from 600mm to 1200mm with a capacity range from 250kg/hour to 1200kg/hour.

Up to 8 raw materials including flame retardant and nucleating agent are automatically loaded and blended before being fed into the primary extruder to produce a homogeneous melt. CO2, plasticizer and / or HFC blowing agents are precisely metered using triple head ATEX compliant, diaphragm pumps with mass flow measurement to ensure a consistent foam density and quality.

The secondary extruder cools the melt using a high mixing, low shear screw and the bimetallic Barrel is water cooled with motorized valve control to minimize temperature variation.

A homogenizing tube and static mixer are positioned prior to the chrome plated flat XPS die which has quick opening and fine tune adjustment bolts and Teflon guide shoes.

The board calibrator with temperature controlled calibration plates and haul off are designed to withstand the expansion pressures of CO2 Board and are fitted with a fail-safe pneumatic quick opening mechanism.

Travel conveyors allow the board to cool before the edges are milled and the board cut to length by our double blade cross cutter capable of handling high line speeds.

The board surface can be planed or grooved to meet market demands and after further cooling, all four edges can be milled again to tongue and groove or shiplap profile or a flat surface.

Foam Insulation Board Extrusion Line provides fully automatic board stacking and 6 sided product wrapping. Product printing, sound proofing and dust extraction can also be provided.

| MODEL | Foam Insulation Board Extrusion Line 120150 XPS | Foam Insulation Board Extrusion Line 150200 XPS | Foam Insulation Board Extrusion Line 180250 XPS |

|---|---|---|---|

| Thickness (mm) | 20~100 | 25~160 | 30~200 |

| Width (mm) | 600, 900, 1,200 | 600, 900, 1,200 | 600, 900, 1,200 |

| Length (mm) | 1,000~3,000 | 1,000~3,000 | 1,000~3,000 |

| Throughput (kg / h) | 300~500 | 500~800 | 800~1,200 |

| Density (kg / M3) | 28~40 | 28~40 | 28~40 |

| Extruder Type | Tandem | Tandem | Tandem |

| Screw Diameter (mm) | 120 and 150 | 150 and 200 | 180 and 250 |

| L / D | 34/1 and 32/1 | 34/1 and 32/1 | 34/1 and 32/1 |

| Blowing Agent | Hydrocarbon, CO2, DME, HCFC, HFC | Hydrocarbon, CO2, DME, HCFC, HFC | Hydrocarbon, CO2, DME, HCFC, HFC |

| Drive System | SIEMENS AC Drive with FLENDER Gearbox | SIEMENS AC Drive with FLENDER Gearbox | SIEMENS AC Drive with FLENDER Gearbox |

| Barrel Material | Bimetallic | Bimetallic | Bimetallic |

| Cooling System | Air Cool for primary, proportional motorized water cool for secondary | Air Cool for primary, proportional motorized water cool for secondary | Air Cool for primary, proportional motorized water cool for secondary |

| Edge Profile | Ship lap, tongue and groove | Ship lap, tongue and groove | Ship lap, tongue and groove |

| Surface Formation | Groove, plane, emboss | Groove, plane, emboss | Groove, plane, emboss |

| Floor Space (M) | 80 m (L) x 15 m (W) x 6 m (H) | 100 m (L) x 15 m (W) x 8 m (H) | 120 m (L) x 20 m (W) x 8 m (H) |